INNOVATIVE

IDEAS

Giving shape to metals

The shaping of metallic semi-finished goods such as sections, bars, tubes, bands, plates and forged semi-finished parts to produce functional components, parts and assemblies for the automotive industry requires a high level of technological manufacturing expertise. This has been acquired and continuously perfected at Fertinger over the last eight decades.

.

Linked production processes

& efficient automation

- Complex products can be created fully automatically through the linking of various production processes. Bringing together operations, machining, cleaning and assembly through to packaging enables efficient component production.

- For example: The automated production line for the manufacturing of connectors links the sawing and machining operations with integrated monitoring and subsequent pre-cleaning in perfect synchronysation.

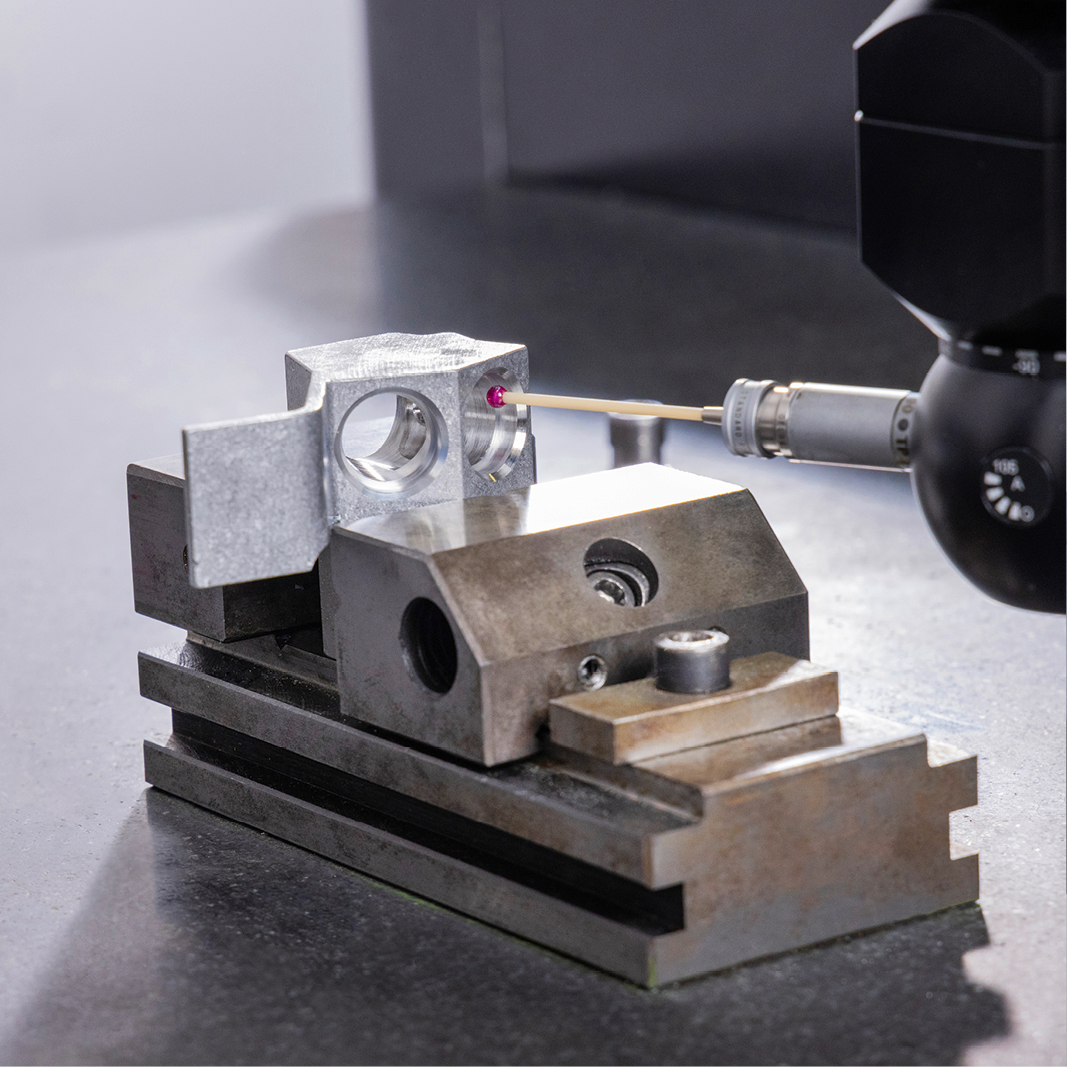

In-house tool shop for component production

100 % product safety &

implementation strength from a single source

Fertinger develops, designs, constructs and manufactures the required production tools itself.

- We offer speed, flexibility and strength of implementation

- “Everything from a single source” – this guarantees 100% product safety.

With our many years of experience in the construction of tools, Fertinger has been able to establish itself as a specialist in metal process tools and component production for the automotive industry.

The tool portfolio includes:

- Jigs for clamping and fixing products in the machines and systems during machining

- Stamping tools, forging dies and tube bending tools

- Tools for tube end processing

- Sample and prototype construction

These tools are manufactured with the support of CAD/CAM on CNC-controlled mills, lathes, grinding machines and eroding machines.