METAL

QUALITY

Metal components for

the automotive industry

As an engineering partner to our customers, we develop and manufacture in series production both products and assemblies for vehicle temperature management. These are finally assembled at renowned TIER 1 companies into air-conditioning unit coolers, oil coolers, charge air coolers, water and battery cooler systems and heat exchangers.

Electrical components: The metallic connection elements in the form of a function-specific battery clamp or stamped cable lugs or busbars represent a further special field in the area of connection technology for current-carrying vehicle parts.

Thermal Management

Components

Aluminium components for climate temperature management for every type of mobility.

Electrical

Components

Metal connection solutions for cable systems – for every type of vehicle.

Components for every type of mobility

Whether conventional, electric, hydrogen or hybrid-powered vehicles – we manufacture components for all types of vehicles.

Thermal Management Components

As a specialist in the production of assemblies and components for cars, trucks and tractors, Fertinger has built up the relevant know-how in the machining/processing of dryer manifolds, blocks, flanges and lugs over decades. Stamped lugs and three-dimensionally bent tubes with finishing as well as the merging of the individual components into complete assemblies round off our product portfolio.

By linking different technologies, Fertinger achieves a very high vertical range of manufacture and is able to assemble complex assemblies for customers in the automotive sector. The assembly is achieved by force fit, form fit or other connecting elements.

We are looking forward to to your enquiries. Contact us now.

Aluminium assemblies

As a system supplier for our TIER 1 customers, we develop, design and manufacture complex assemblies from various individual components.

- Pierced or punched manifolds

- Pre-assembled assemblies of manifolds, connection blocks and mounting brackets

- Dryer bottles including manifold assembly

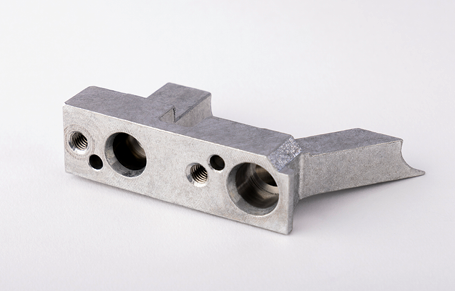

Connecting elements

The requirements for the production of aluminium components are as individual as our customers from the most diverse industrial sectors. Highest precision and perfection down to the smallest detail are always a basic requirement for us.

- Connection blocks

- VDA connectors

- Valves

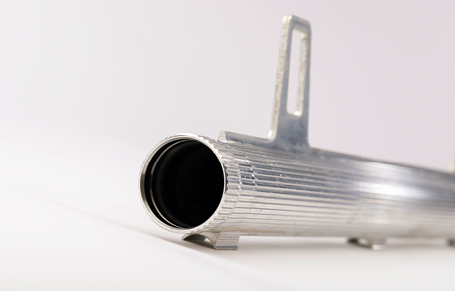

Dryer tubes

Every year we produce over 3 million dryer tubes. This makes us the leading provider in Europe. Fully automated production facilities and a technically high-quality manufacturing concept ensure smooth production according to requirements.

- Dryer tubes up to 480 mm length

- Automated sub-assembly of end caps possible

- Position of the connection holes and other details freely selectable

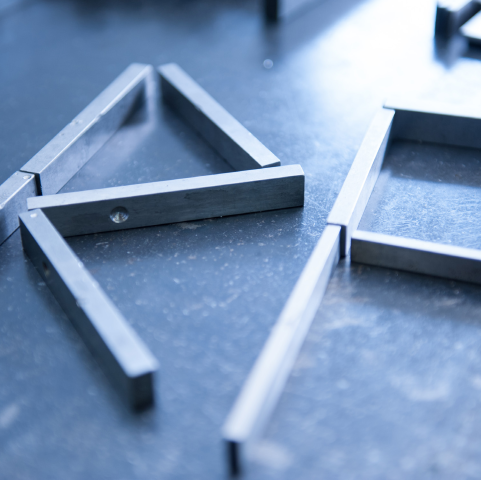

Mounting brackets

We develop and produce various aluminium mounting brackets for your application areas.

- Extruded mounting brackets

- Punched mounting brackets

- Aluminium bracket elements

- Cut mounting brackets

Pre-assembly of piping

Automated bending and forming machines from Rupert Fertinger GmbH bring your aluminium pipes into shape. This flexibility allows us to realise any geometry and connection points.

- Curved and shaped piping

- Pre-assembled pipes and connecting elements

Aluminium solder assemblies

A prerequisite for the production of high-quality solder assemblies is a fully equipped peripheral infrastructure in addition to high-performance plant technology.

These include, in particular, cleaning systems for component cleaning and systems for leak testing.

Electrical connection components

- Metallic connection elements, such as in the form of function-related battery clamps in automobiles, are processed fully automatically at Fertinger. The final surface treatment (tinning or nickel plating) is carried out flexibly and quickly with our European partners, depending on customer requirements.

- On request, we can also fit various add-on parts and connection elements. We offer complete cable assembly for small and medium series. At Fertinger, brass is the preferred raw material for this application, but aluminium and special alloys are also used.

- Stamped cable lugs and busbars made of copper, brass and bronze are another speciality in the field of connection technology for current-carrying parts in vehicles.

- In addition to the current-carrying components, we stamp shielding housings and retaining elements for various applications in vehicles.

All products are developed together with our customers from the first draft to series production readiness and can also be integrated into assemblies if required.

Connecting Solutions

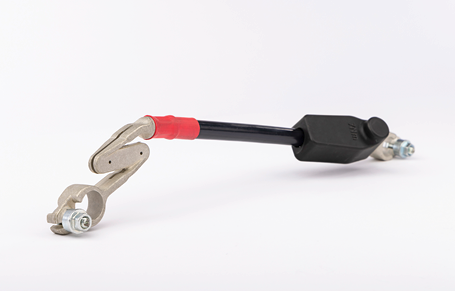

Battery clamps

In cooperation with our partners, we develop and produce simple and complex battery clamps made of brass. The surface can be supplied either bare or with a Ni/tin coating, depending on the customer’s requirements.

The production of stamped battery clamps made of brass and copper rounds off our product portfolio.

Stamped cable lugs

Every vehicle needs a multitude of different connecting elements and requires a concept that is compatible with the installation space.

We support our customers in the layout and design of cable lugs with small or large cross-sections. The materials used can be copper, brass, bronze or even aluminium.

Shielding enclosure

Elements for shielding interference elements or as a protective function in BEV vehicles can be punched in customised designs thanks to our innovative manufacturing concept.

Highest precision in tool design as well as in the manufacturing process is a prerequisite to achieve high product quality.

Retaining elements

These stamped components, mainly made of steel, allow a variety of sub-assembly options in the engine compartment.

The necessary progressive die cutting tools are designed and built in our own tool manufacture. This allows a quick and flexible realisation and a high output.

Cable assembly

Different individual components can be joined together with a copper cable to form a ready-made assembly.

The focus on small series allows a wide range of possibilities for our customers.

Sub-assembly

Battery clamps, cable lugs or various holding elements often require additional connection parts.

Here we offer a wide range of options, e.g. the loss-proof assembly of insert nuts, threaded bolts or screws.

Contact me!

I am looking forward to your requests and questions.

DI (FH) Thomas Menitz, MBA

Head of Sales

+43 2245 3211 122

sales@fertinger.at